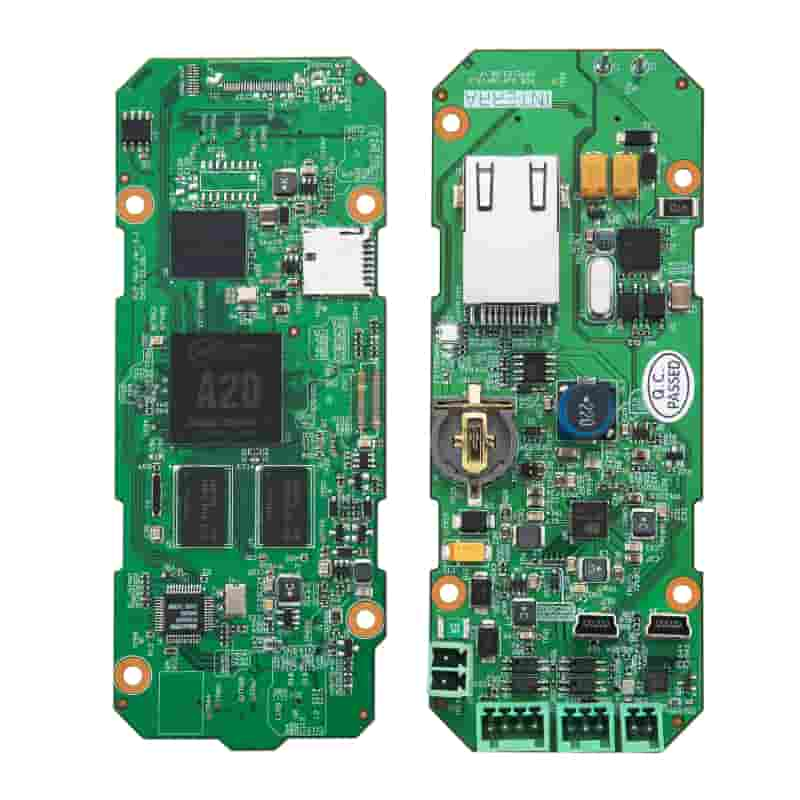

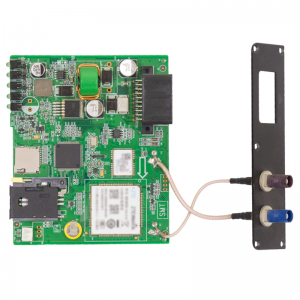

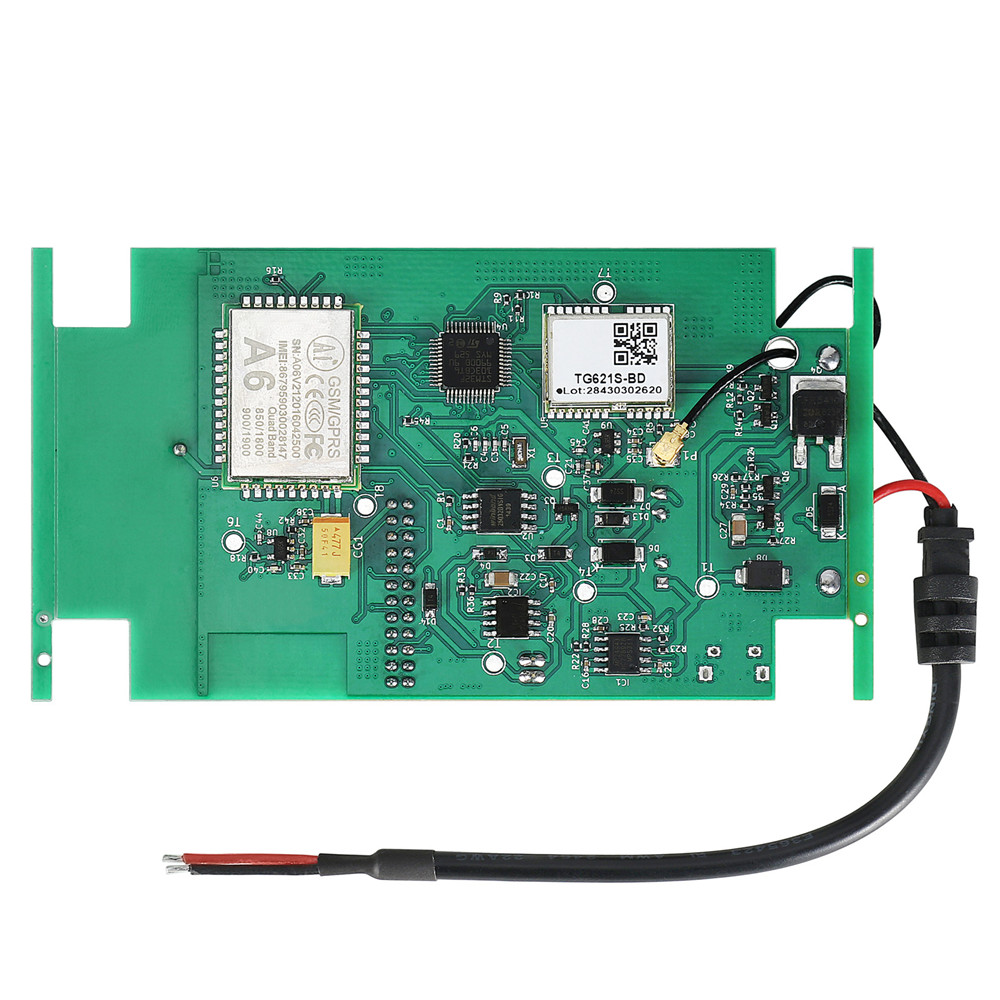

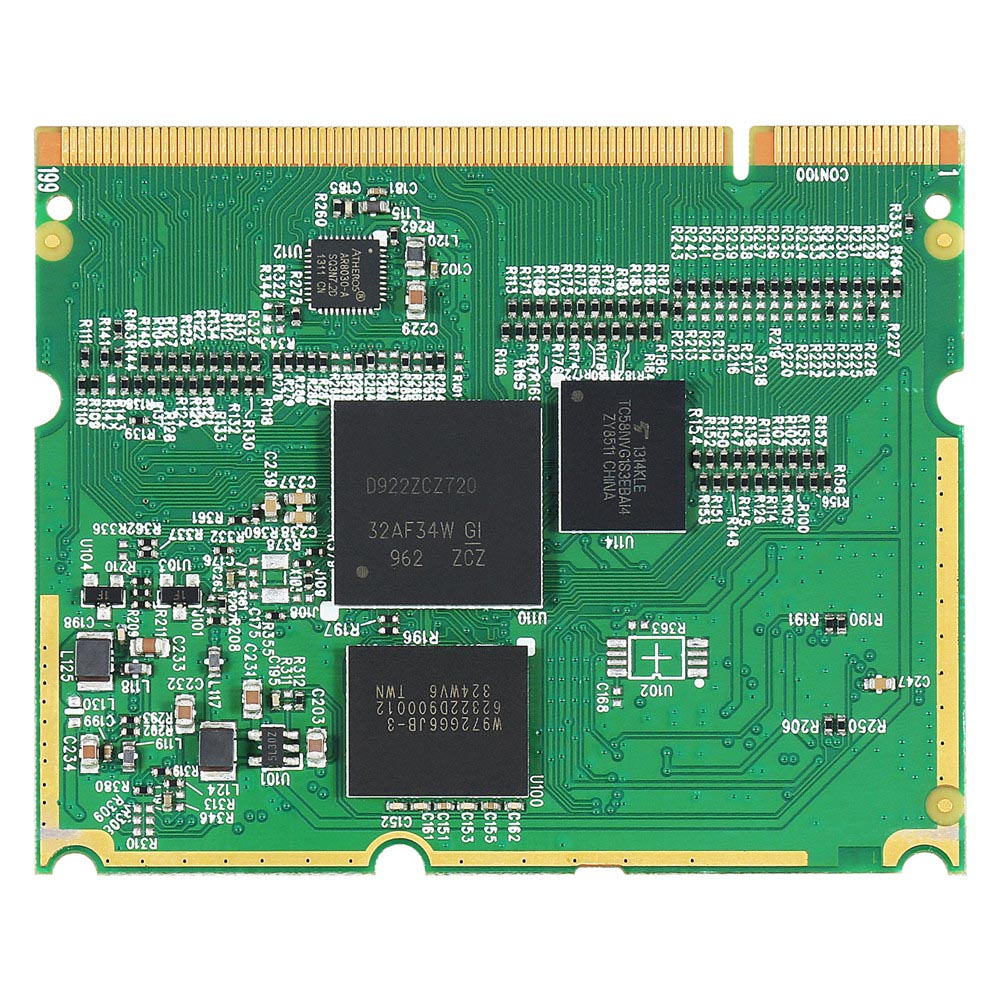

Automotive electronics PCBA board

Products feature

● -Reliability testing

● -Traceability

● -Thermal management

● -Heavy copper ≥ 105um

● -HDI

● -Semi - flex

● -Rigid - flex

● -High frequency milimeter microwave

PCB structure characteristics

1. Dielectric layer (Dielectric): It is used to maintain the insulation between lines and layers, commonly known as the substrate.

2. Silkscreen (Legend/Marking/Silkscreen): This is a non-essential component. Its main function is to mark the name and position box of each part on the circuit board, which is convenient for maintenance and identification after assembly.

3.Surface treatment (SurtaceFinish): Since the copper surface is easily oxidized in the general environment, it cannot be tinned (poor solderability), so the copper surface to be tinned will be protected. The protection methods include HASL, ENIG, Immersion Silver, Immersion TIn, and organic solder preservative (OSP). Each method has its own advantages and disadvantages, collectively referred to as surface treatment.

PCB Techinecal Capacity

| Layers | Mass production: 2~58 layers / Pilot run: 64 layers |

| Max. Thickness | Mass production: 394mil (10mm) / Pilot run: 17.5mm |

| Material | FR-4 (Standard FR4, Mid-Tg FR4,Hi-Tg FR4, Lead free assembly material) , Halogen-Free, Ceramic filled , Teflon, Polyimide, BT, PPO, PPE, Hybrid, Partial hybrid, etc. |

| Min. Width/Spacing | Inner layer: 3mil/3mil (HOZ), Outer layer: 4mil/4mil(1OZ) |

| Max. Copper Thickness | UL certificated: 6.0 OZ / Pilot run: 12OZ |

| Min. Hole Size | Mechanical drill: 8mil(0.2mm) Laser drill: 3mil(0.075mm) |

| Max. Panel Size | 1150mm × 560mm |

| Aspect Ratio | 18:1 |

| Surface Finish | HASL,Immersion Gold, Immersion Tin, OSP, ENIG + OSP, Immersion Silver, ENEPIG, Gold Finger |

| Special Process | Buried Hole, Blind Hole, Embedded Resistance, Embedded Capacity, Hybrid, Partial hybrid, Partial high density, Back drilling, and Resistance control |

Our automotive electronics PCBA boards are a revolutionary product designed to meet the high demands of the automotive industry. As one of the leading automotive PCB manufacturers, we have accumulated rich experience in production control process and technology to ensure the highest quality and reliability for our customers.

Our automotive products are extremely diverse and include Heavy Copper Board, HDI (High Density Interconnect), High Frequency and High Speed board categories. These boards are designed for the production of connected mobility, automated mobility and increasingly electrified vehicular mobility.

With the rapid advancement of automotive technology, there is an increasing demand for electronic components that can withstand longer life, higher temperature loads and finer pitch designs. Our automotive PCBA boards are specifically designed to meet these needs, delivering superior performance and reliability in the harsh automotive environment.

One of the key features of our PCBA boards is the ability to handle thick copper, which is critical for applications requiring high current and power transfer capabilities. This makes our boards ideal for electric and hybrid vehicles where power management is critical.

Additionally, our HDI technology ensures the board has a compact design and high circuit density, making it ideal for applications requiring a smaller form factor. This allows automakers to design sleek and compact systems without compromising functionality.

Additionally, our high-frequency and high-speed board designs enable seamless integration of advanced functions such as radar systems, autonomous driving functions, and advanced driver assistance systems (ADAS). These boards provide excellent signal integrity, ensuring accurate and reliable data transmission in real time.

At our company, we prioritize customer satisfaction and strive to exceed expectations by delivering first-class products that meet the highest industry standards. Our automotive electronics PCBA boards are no exception, offering superior quality, reliability, and performance for your automotive applications.

In summary, our automotive electronics PCBA boards are the perfect solution for car manufacturers looking to enhance their automotive electronics systems. With our extensive experience, diverse product offerings, and commitment to quality, we are confident that our board will meet and exceed your expectations. Trust us to provide you with cutting-edge technologies for the future of mobility.