SMT processing is a complex process involving multiple processing steps, some engineers may solder SMD components themselves, but I will tell you why it should only be handled by qualified professionals.

First of all, what is SMT welding processing?

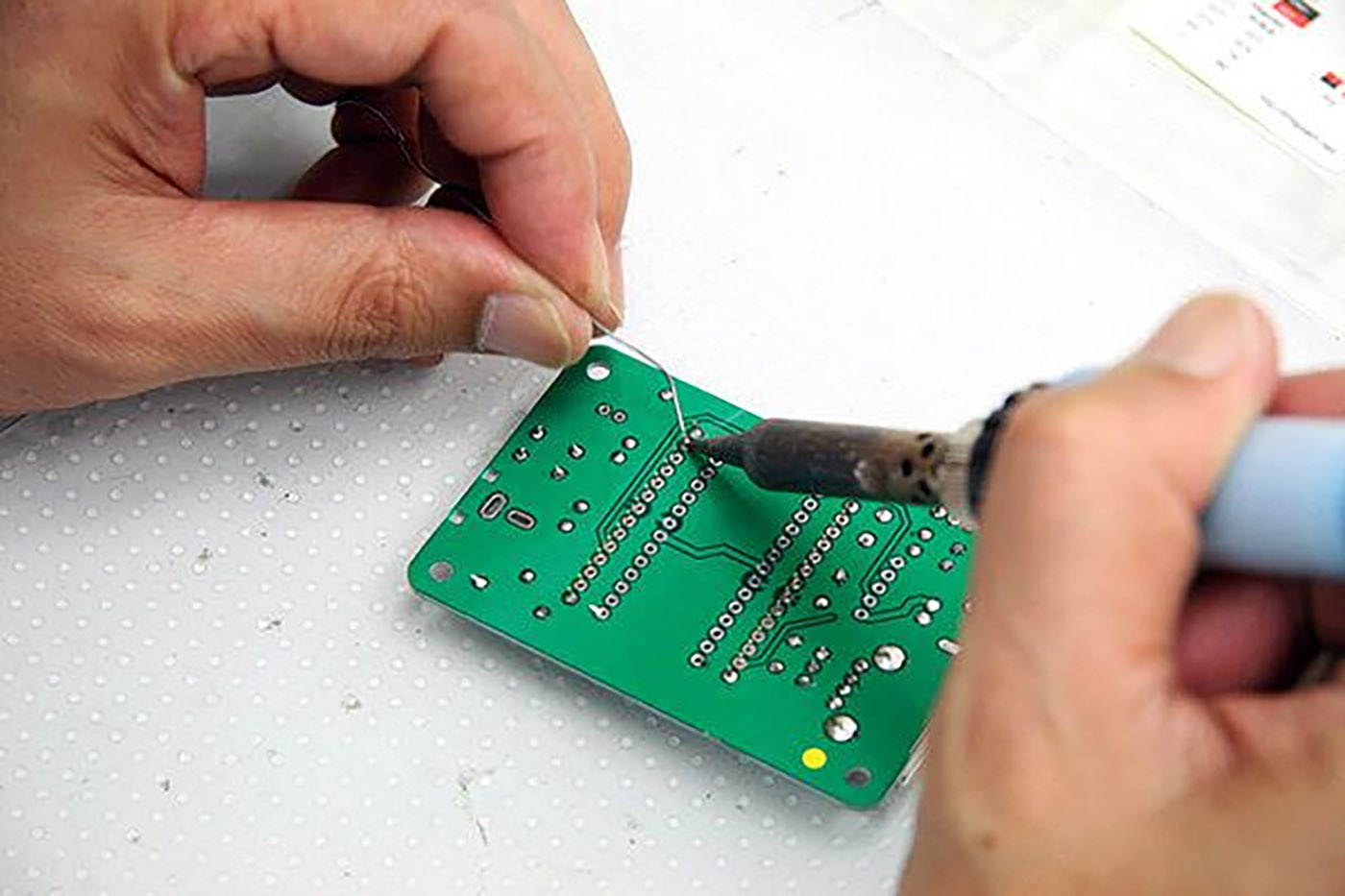

When soldering components on a PCB, there are two main technologies, Through Hole Technology (THT) and Surface Mount Technology (SMT). THT was mostly used on older circuits without SMT, and is now only used on amateur and amateur circuits. The through-hole soldering process involves drilling holes in the PCB, mounting electronic components on the PCB, and soldering the component leads to the copper wires on the other side of the board. This welding process is expensive, slow, cumbersome and cannot be automated. In addition, components with lead terminals tend to be bulky, making them unsuitable for modern electronic circuits with critical form factor requirements.

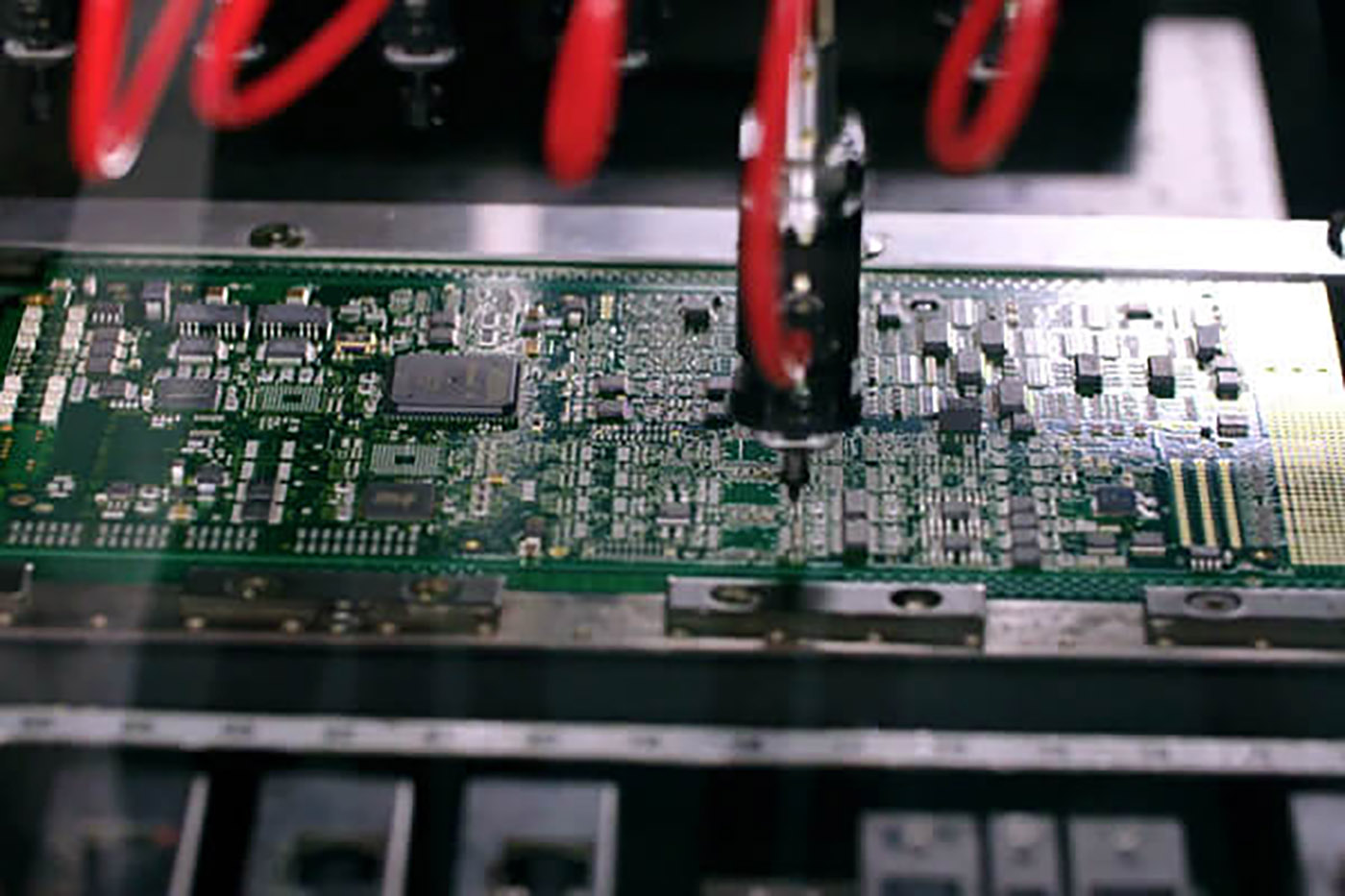

Today, SMT processing has almost replaced traditional soldering methods in PCB manufacturing. In SMT soldering, components are placed directly on the surface of the PCB rather than through drilling. Surface Mount Devices ( SMD ) have a much smaller footprint than traditional THT components. For this reason, a large number of SMD components can be packed into a smaller area, enabling very compact and complex electronic circuit designs. Another great advantage of SMT component soldering is that the process can be fully automated, increasing accuracy, speed, efficiency and cost-effectiveness. Today, SMT soldering is now the default PCB assembly method.

Why should SMT processing be handed over to a professional company?

There is no doubt that SMT component soldering has many advantages, but the process is far from simple. In fact, professional SMT soldering is a complex process involving multiple process steps. Given the complexity of the process and the required level of expertise, SMT soldering work must be performed by trained professionals.

• Special tools and machines

• Component procurement

• skills and expertise

The tools and machines required for SMT soldering are often very expensive. It can be difficult for a novice to set up a proper laboratory with all the necessary tools and machines as it can cost a fortune. However, a professional SMT processing company like Pinnacle has the right setup for all the necessary equipment. Therefore, outsourcing SMT can make the workflow easier, straightforward and cost-effective.

In addition to providing tools and machines, know-how and know-how are just as important. Machines are useless without proper expertise. SMT soldering is a complex process that requires a lot of dedication and practice to master. Therefore, it is more efficient to leave the task of assembly to professionals than to reinvent the wheel yourself. Additionally, companies with SMT soldering expertise also specialize in component sourcing, which allows them to source components faster and cheaper.

The SMT component soldering market was valued at USD 3.24 billion in 2016 and is expected to grow at 8.9% during 2017-2022. The SMT market is a huge market with many market segments. The target audience includes IC designers, OEMs, product manufacturers, R&D institutions, system integrators and consulting firms.

Because precision printed circuit boards are used in all walks of life, there is no field that is not related to SMT technology. Focus areas include consumer electronics, telecommunications, aerospace and defense, automotive, medical and industrial electronics.

Post time: Mar-29-2023