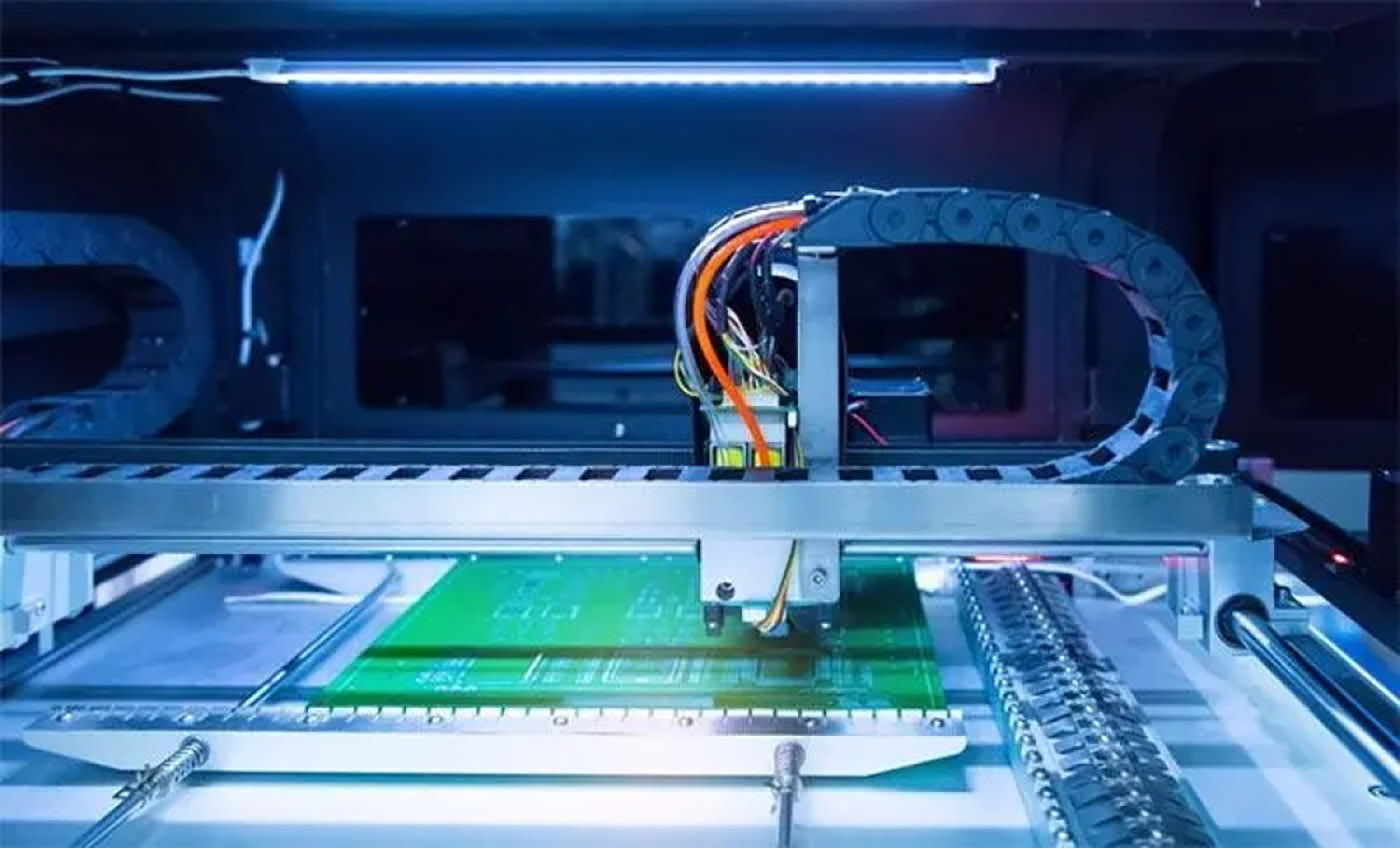

In the process of PCBA processing and production, the generation of static electricity is generally unavoidable, and there are many precision electronic components on the PCBA board, and many components are more sensitive to voltage. Shocks above the rated voltage can damage these components. However, it is difficult to check the PCBA board damaged by static electricity step by step during functional testing. The most harmful thing is that the PCBA board is still good when it is detected, but there is a problem in the hands of the user, which not only causes inconvenience to the user, but also affects the company's brand and goodwill. Therefore, electrostatic protection is particularly important during PCBA processing.

Static protection method

In the production process of electronic products, there are two basic principles of static electricity protection: one is to prevent the accumulation of static electricity in places where static electricity may "Release" to eliminate the accumulation of static electricity and control it within a safe range; the second is to quickly, safely and effectively eliminate the static charge that has already been generated, that is, to take measures for the existing static charge accumulation to make it quickly Dissipate, instant "vent".

Therefore, the core of electrostatic protection in the production of electronic products is "static elimination" and "static grounding".

1. The static electricity on the conductor can ground the parts that may or have already generated static electricity, release the static electricity in time, and use the static grounding monitor to detect the grounding status.

2. For the static electricity on the insulator, since the charge cannot flow on the insulator, the static charge cannot be removed by grounding, but can only be controlled by the following methods.

Use an ion blower. The ion fan can generate positive and negative ions to neutralize the static electricity of the static source. It is used in places where static electricity cannot be discharged through grounding, such as space and near the placement machine head. Using an ion fan to eliminate static electricity usually has a good anti-static effect.

Control the humidity of the environment. The increase of humidity can increase the surface conductivity of non-conductive materials, so objects are not easy to accumulate static electricity. In dangerous places with static electricity, when the process conditions permit, a humidifier can be installed to adjust the humidity of the environment. For example, in factories in the north, static electricity is likely to be generated due to low ambient humidity. The use of humidification methods can reduce the possibility of static electricity. This method is effective and cheap.

Post time: Mar-03-2023